January 7, 2026

At Charles Nobel, bespoke is never “one-size-fits-all”. It is a structured, collaborative process that balances design intent with real-world wearability, engineering, and finishing standards. This project is a perfect example: our client wished to commission two distinct outcomes from one cohesive design story:

Below is a step-by-step view of how we brought the collection to life—from concept sketches through to the finished pieces.

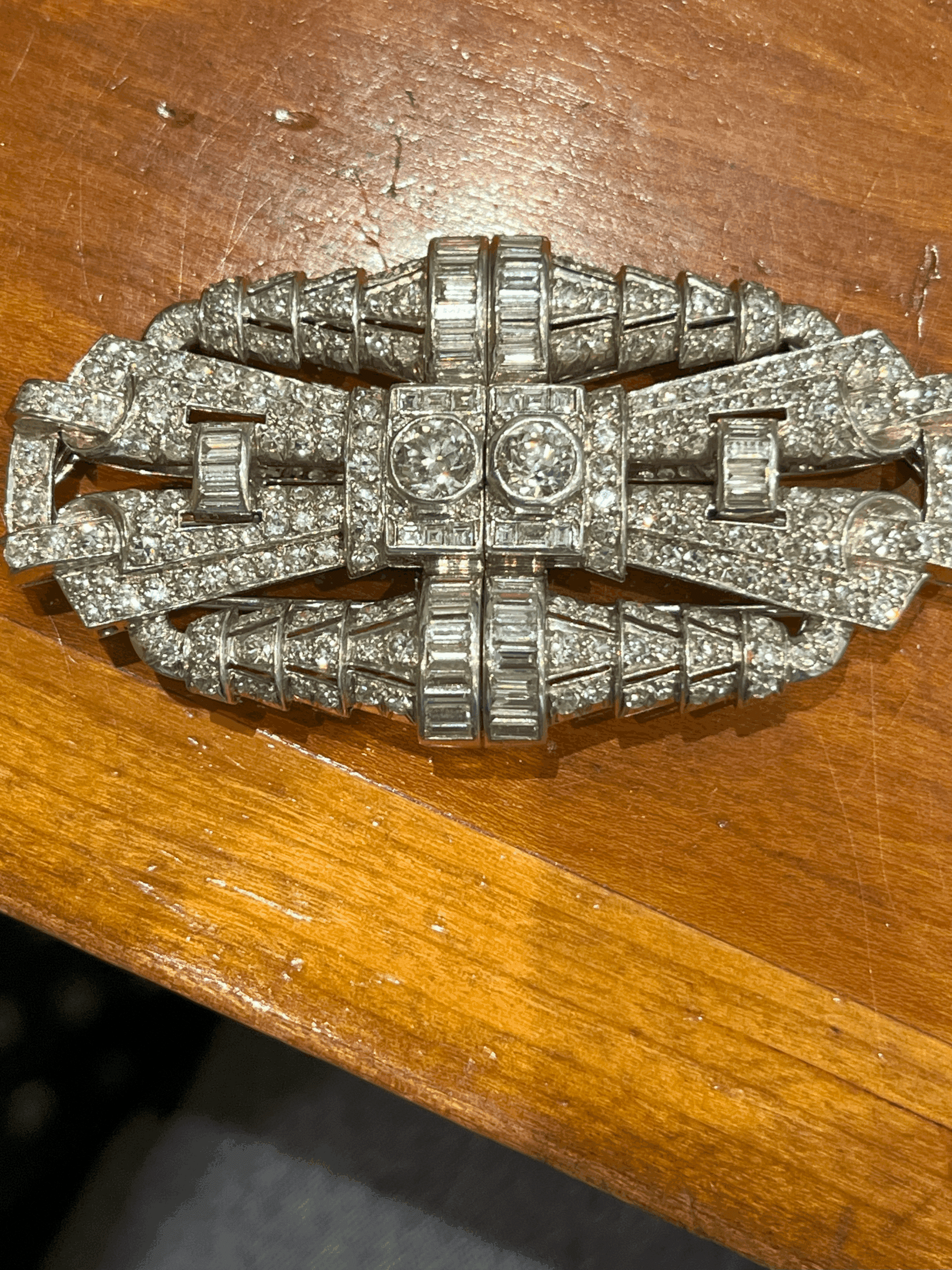

Every successful bespoke project begins with understanding what the client already loves.

For this commission, the client’s original set featured a distinctly geometric, architectural look—clean lines, strong symmetry, and a refined interplay of round and baguette-cut diamonds. Our job was to respect those design cues while ensuring the new pieces felt purposeful rather than copied.

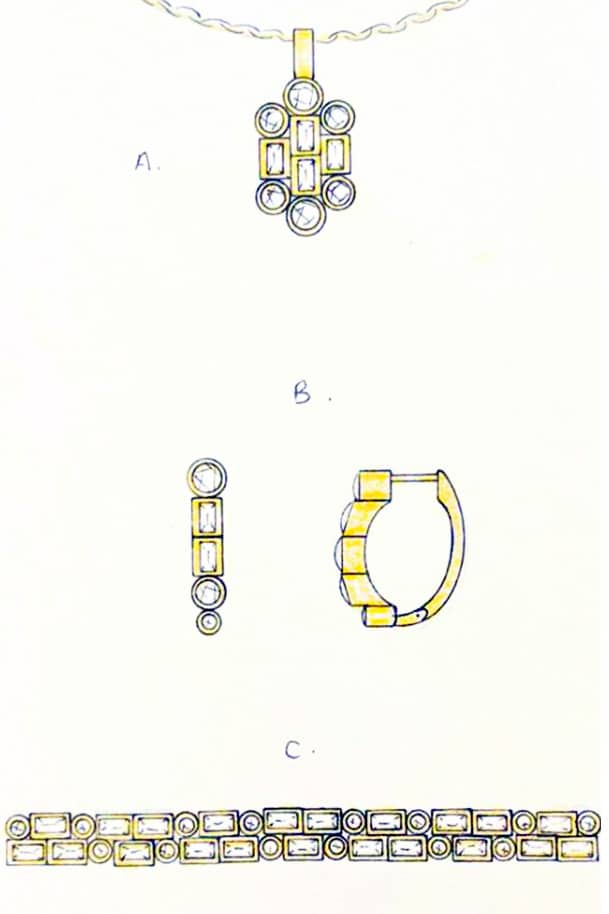

We structured the work into two design streams:

We presented hand-drawn design concepts for each element—mapping out proportions, stone placement, and how the motifs could translate across different formats (pendant vs. earring vs. bracelet). This is where the client experience matters most: the best bespoke pieces are the result of clear decisions made early, with visuals that are easy to respond to.

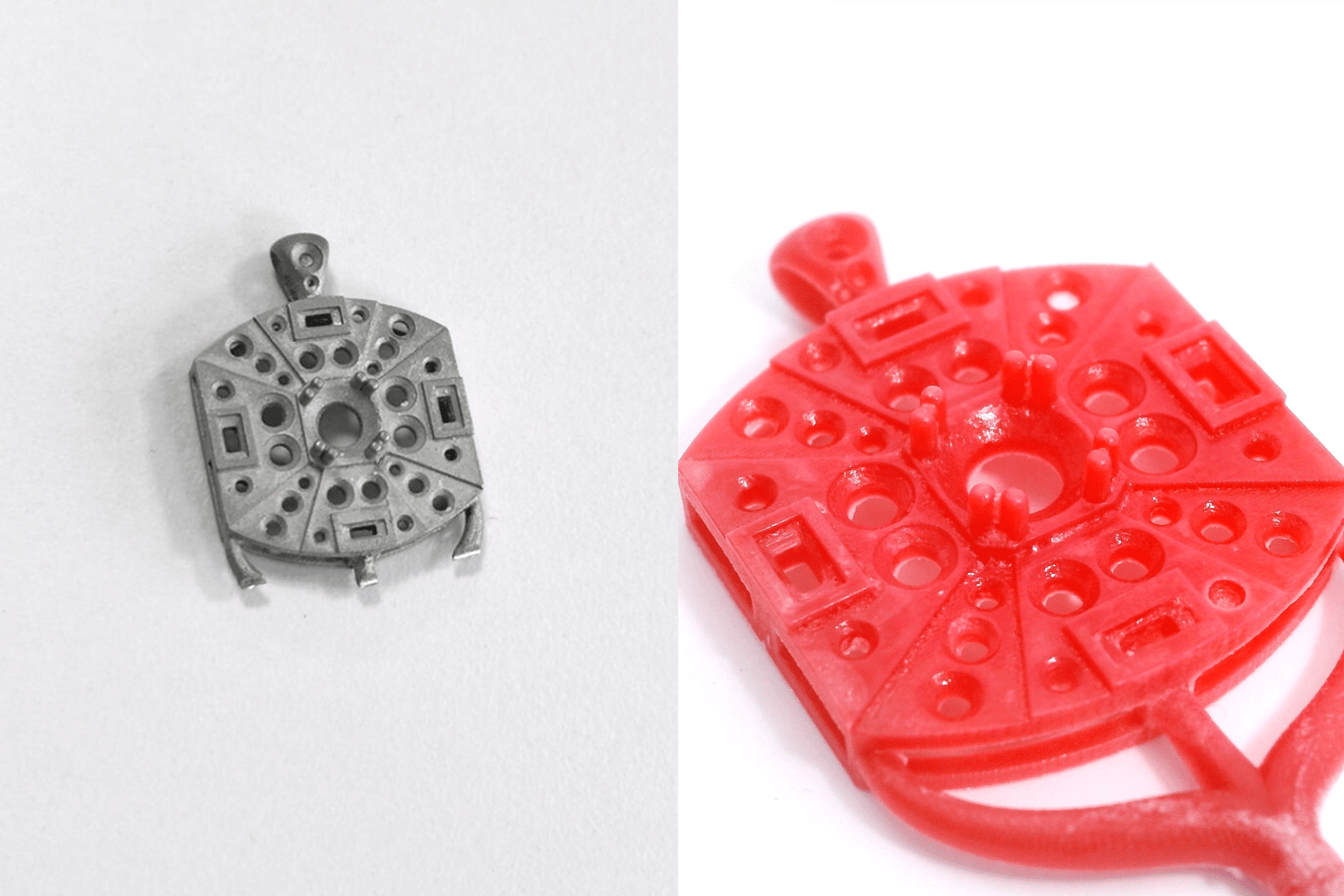

With the designs signed off, our team translated the sketches into production-ready forms. This is the stage where bespoke becomes technical.

We use CAD to define:

CAD allows us to “solve” the piece before it exists—minimising risk, optimising finish, and ensuring each stone setting is engineered correctly for long-term wear.

From CAD, components are prepared for casting in the correct metal:

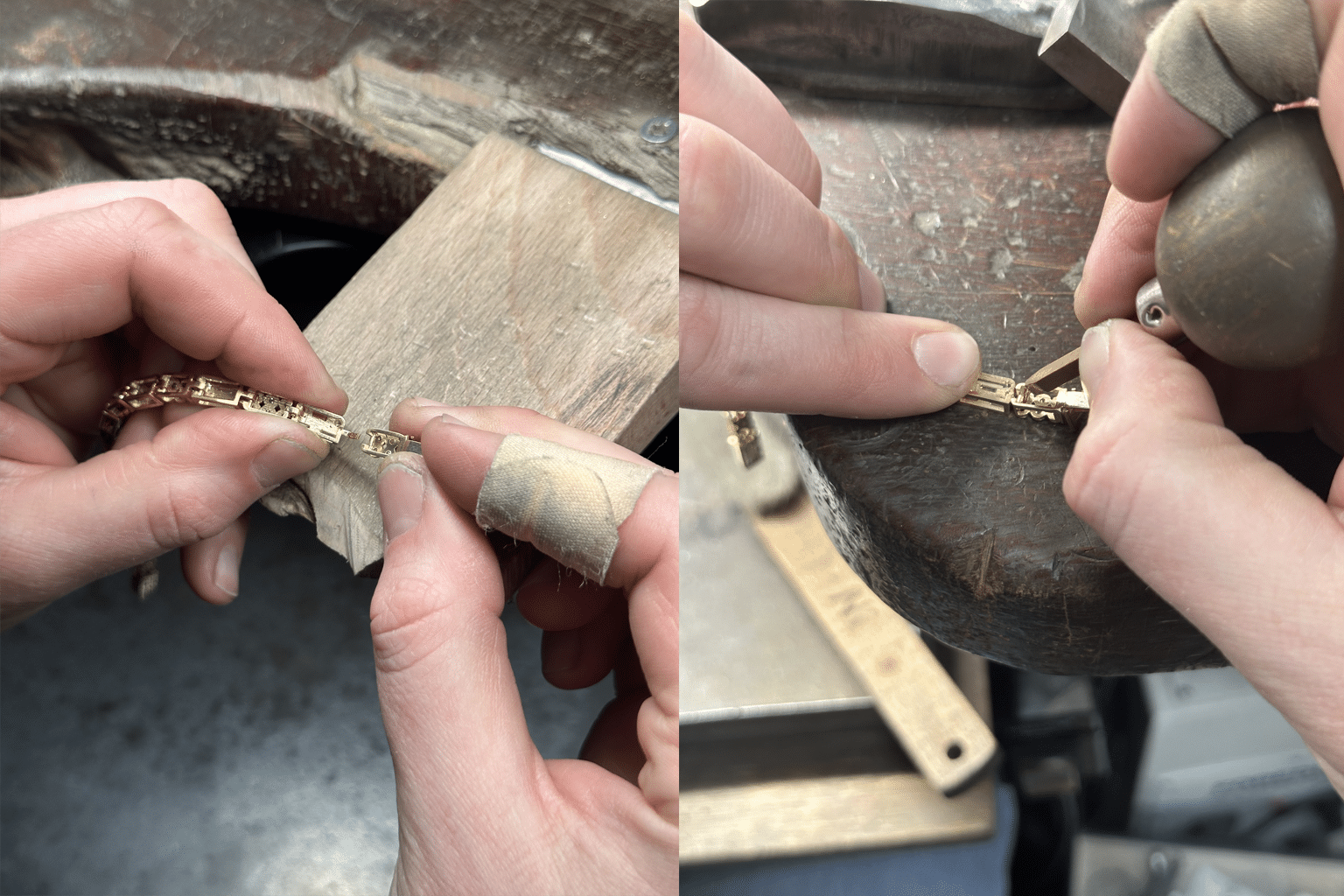

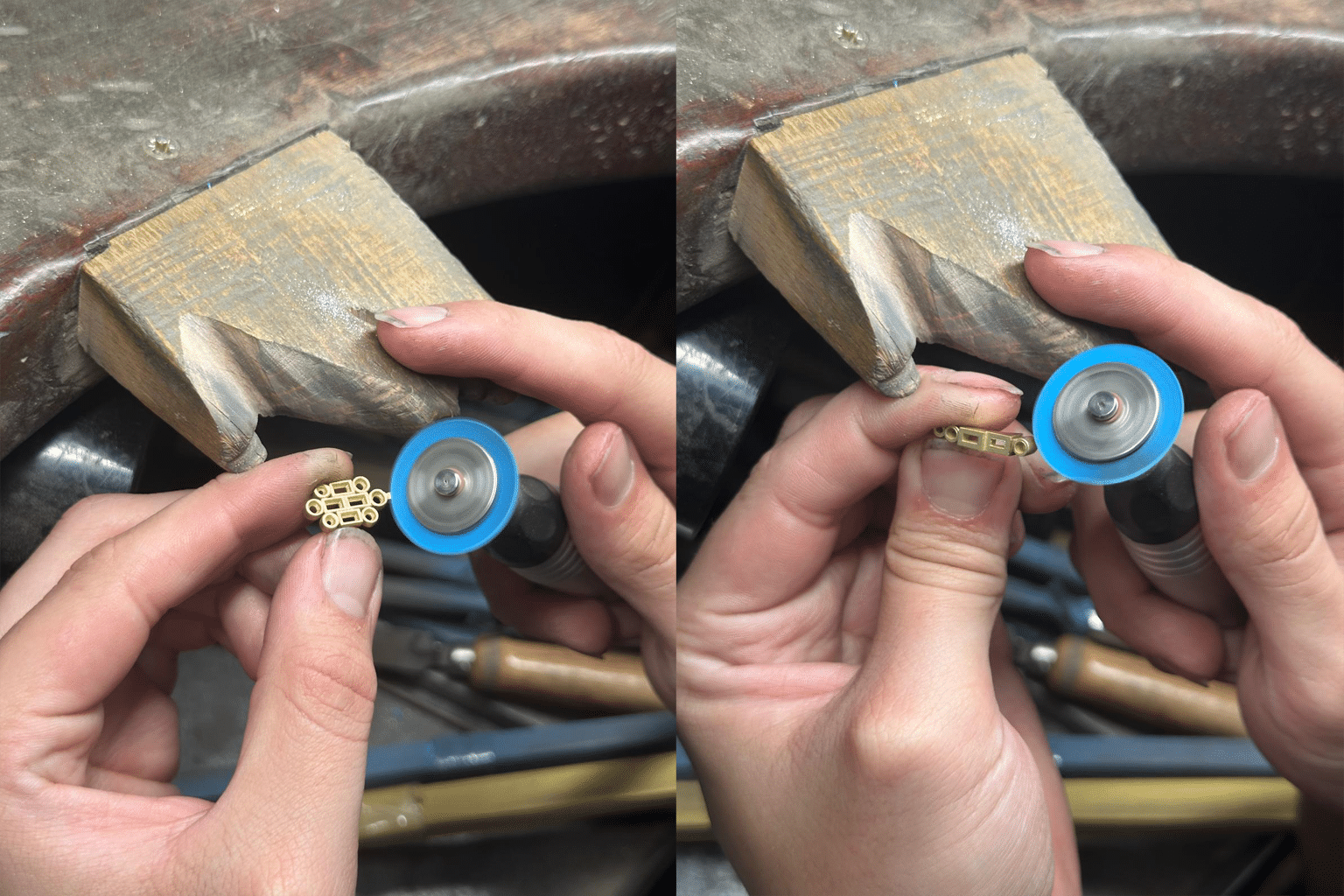

The newly cast parts then go through the first stages of bench work—cleaning, refining edges, preparing joints, and bringing each component into alignment before assembly.

This is where craftsmanship becomes visible.

The 18ct yellow gold pieces were constructed as a coordinated set, with repeated motifs across:

Bracelets demand particular attention: each link must align perfectly, articulate smoothly, and remain robust under daily wear. We refine and test movement repeatedly during this phase, ensuring the bracelet feels as good as it looks.

Before any diamonds are set, each piece is prepared so that:

Stone setting is the moment the jewellery truly comes alive.

For the platinum pendant, we focused on a sophisticated, structured finish—one that complements the existing jewellery and maintains that elegant, architectural feel. The combination of round and baguette-cut diamonds creates contrast and rhythm, while the platinum brings brightness and a crisp outline to the design.

The yellow gold suite was finished to a high standard, balancing warmth from the gold with the brilliance of the diamonds. The repeated geometric motifs across the suite create a clear identity: each piece stands alone, but together they read as a complete collection.

Clip earrings were finished with particular care—comfort, security, and profile are crucial. The aim is a piece that feels substantial and luxurious, yet practical and easy to wear.

Before delivery, we complete:

Only once everything meets standard do we photograph and present the final pieces.

This project delivered exactly what bespoke should: jewellery that feels deeply personal, perfectly considered, and built to last.

If you have an existing piece you love—and you want to extend it, modernise it, or create a new suite that complements it—we can guide you through a clear, structured bespoke process from design through to delivery.